Electrical Thermal Imaging

Infrared thermographic inspections are excellent for electrical installations. Equipment can be surveyed under normal operating conditions without disturbance to operation at a safe distance. Thermal Imaging can be used for routine testing and inspections of existing electrical installations. The process is far more efficient and reliable than other maintenance techniques.

The requirement for periodic inspection testing and reporting is set out in Regulation 89 of the 2007 Safety Health and Welfare at Work (General Application) Regulations (S.I. No 299 of 2007) as amended by the Safety, Health and Welfare at Work (General Application)(Amendment) Regulations 2007(S.I. No. 732 of 2007) ).

In addition with complying with HSA guidelines for testing and inspection, some insurance firms also require routine testing and inspections.

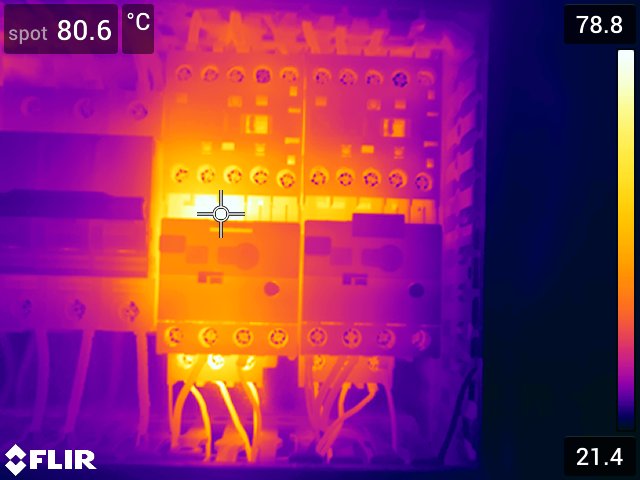

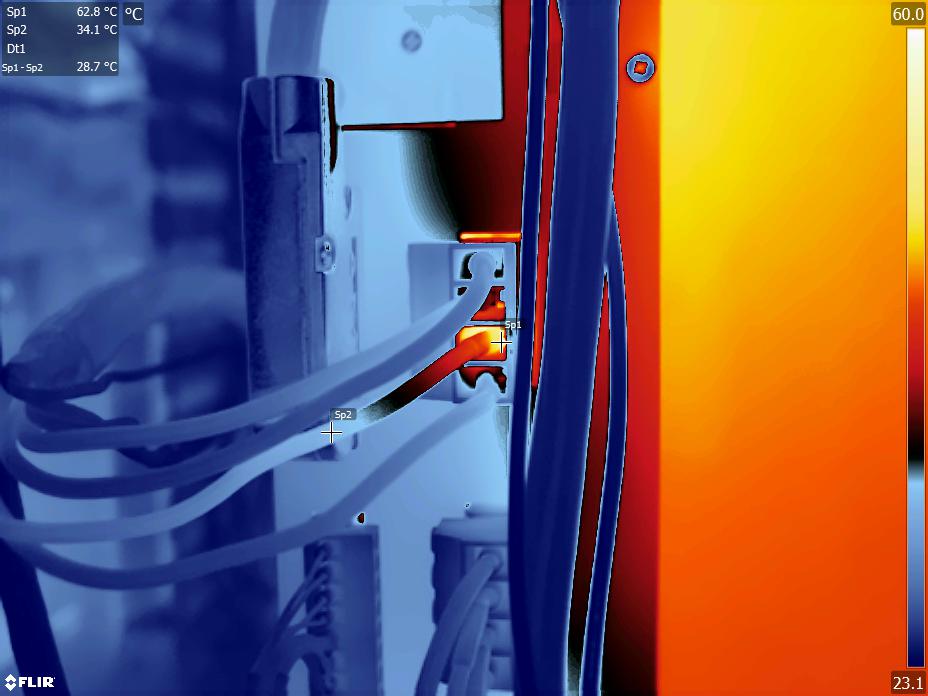

As electrical equipment age or connections become loose, the resistance to current causes an increase in temperature. If left unchecked, faults can deteriorate causing connections to melt which may result in a fire hazard. Also component failure can lead to extensive downtime leading to financial loss. An electrical thermal imaging survey can quickly identify the following faults:

- Loose connections

- Phase imbalances

- Arcing

- Undersized cables

- Overloading

- Faulty breakers / Fuse holders

- Seized Fans

- Any electrical defects that result in the generation of heat can be readily identified and resolved using infrared techniques.

Thermal Imaging Reports

Spectrocity provides detailed reports including visual and thermal images, accompanied with detailed analysis on root cause and suggested repairs. We do not carry out repairs or recommend contractors, this is an impartial survey. Reports also include sign off sheets for repairs and can be tailored to your needs. The retention period for the signed reports is 5 years. With extensive experience in automation and electrical safety, we have the skills to work with you to assist in solving problems.

Some examples of fault detection's can be seen below.

A brief description of the faults can be seen on the bottom of the images.